BITZER offers a wide range of condensers, evaporators, receivers, oil separators and oil coolers. With series for all sorts of refrigerants and coolants, you will find the right component for every system. Many are available with a wide range of materials and certifications.

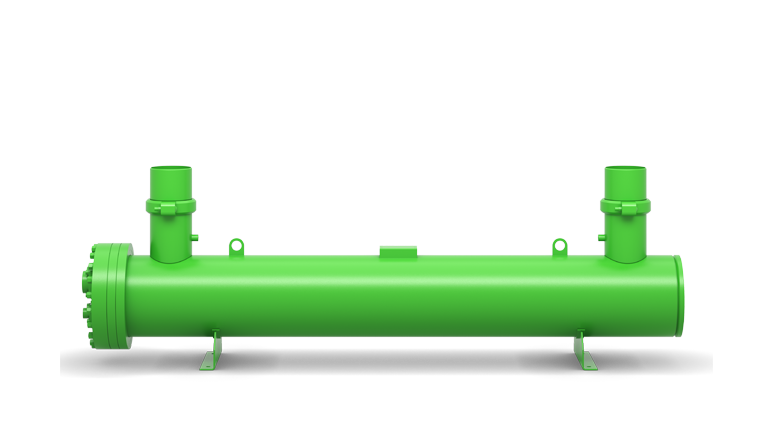

Five series of water cooled condensers with a standard capacity of up to 1,680 kW satisfy all condensation needs with versions for normal/technical water and for seawater. HFC, HFO, HFC/HFO blends, propane and NH3 can be used as refrigerants. A complete selection of pressure vessel approvals and certifications for stationary and marine applications is available.

Dry-expansion evaporators designed with ‘U-tube’ or with a single-pass design, combined with patented refrigerant distribution systems, offer the best performance and the lowest approach between evaporation temperature and water-leaving temperature for positive, medium and low (down to –40°C) applications. A selection of materials and a wide approval choice is available. Flooded evaporators offer the highest efficiency available in the industry.

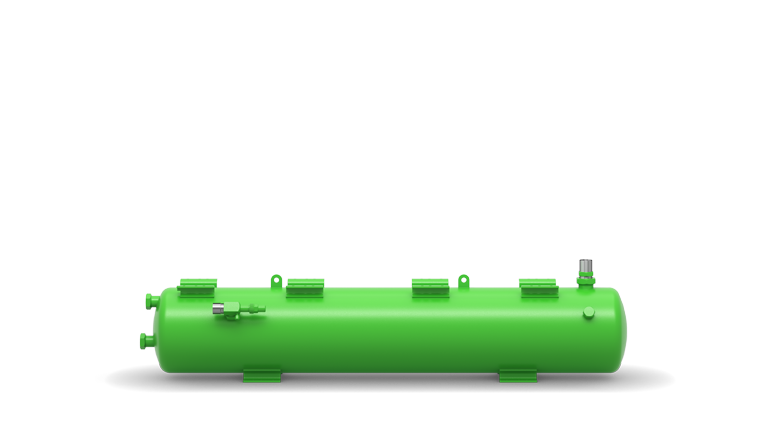

The horizontal and vertical liquid receivers are available for HFC/(H)CFC refrigerants, ammonia, hydrocarbons and carbon dioxide and fulfil the various requirements of refrigeration and air-conditioning technology. Operating temperatures of –10°C to 120°C are possible with a maximum allowable pressure of 45 bar.´

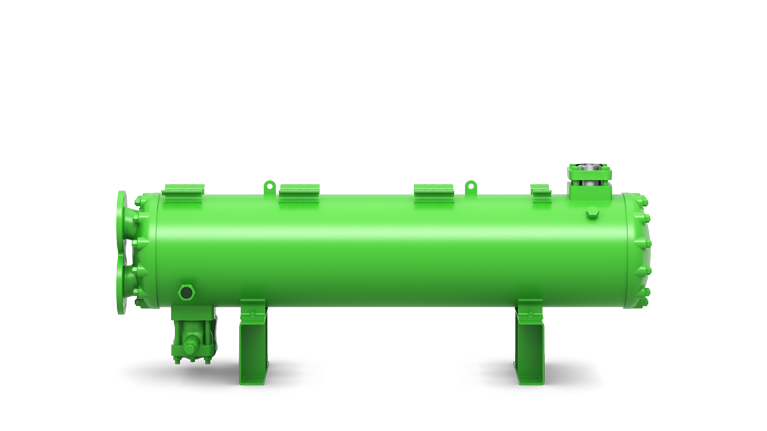

A complete range of vertical and horizontal solutions that ensure perfect oil separation during full- and part-load operation for single compressors and compound systems. Versions are available for HFC, HFO, HFC/HFO blends or for NH3, with one, two or three steps, or for operation with flooded systems.

BITZER offers five condenser series that can be used in HFC and HFO systems. Notably low approach performances can be reached with standard capacities of up to 1680 kW. Water cooled and air cooled oil coolers ensure additional cooling, with low pressure drop values and reduced energy consumption

GK water gas coolers are a family of heat exchangers designed for CO₂ applications and can be used as gas coolers in transcritical systems, heat recovery heat exchangers or condensers in subcritical systems. The primary medium (CO₂) flows on the tube side, thanks to the high design pressure, while the secondary medium (water or antifreeze mixtures) runs on the shell side. The countercurrent flow design between the primary and the secondary medium ensures that reduced thermal approaches between the two fluids are possible, thus enhancing the performance of these heat exchangers in both transcritical (gas cooler or heat recovery) or subcritical (condenser) modes.

Pulsation mufflers reduce discharge gas pulsations in the discharge lines and considerably lower vibration in systems should they reach a critical level. This, in turn, reduces the risk of damage resulting from leakage or pipe fractures. Pulsation mufflers are not a replacement for expert design/operation of refrigeration systems.